News Release

FY2019

February 7, 2020

JX Nippon Mining & Metals Corporation

Bench-scale Equipment for Recycling Automotive Lithium-ion Batteries Goes Into Operation

-- On the Way to Realizing Closed-Loop Recycling --

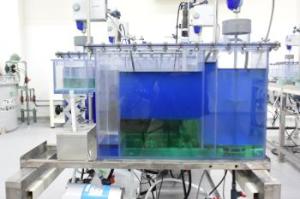

JX Nippon Mining & Metals Corporation (President: Seiichi Murayama; “the Company”) has installed bench-scale equipment* in the Hitachi Works (Hitachi, Ibaraki Prefecture) for recycling of lithium-ion batteries used in automobiles, and has started equipment operation. In anticipation of a time when end-of-life lithium-ion batteries from automotive vehicles are discarded in large numbers, research and development are accelerating toward realizing “closed-loop recycling,” recovering rare metals from these discarded batteries and using them again as automotive battery materials.

Rising environmental awareness globally is behind the rapidly growing popularity of electrical vehicles and other next-generation automotive vehicles with small environmental burden. Since most of these vehicles use lithium-ion batteries, demand for cobalt, nickel, lithium, and other rare metals used in making their cathode materials is expected to grow. Accompanying this trend, in five to ten years the volume of discarded automotive lithium-ion batteries is likely to swell, so that a key issue for both effective use and stable supply of resources will be the ability to recover rare metals from these end-of-life batteries.

The Company is already conducting demonstration tests for recycling of consumer-use lithium-ion batteries at its Tsuruga Plant (Tsuruga, Fukui Prefecture), the largest operation of its kind in Japan, and has technology for recovering rare metals not from discarded cathode materials but from discarded batteries themselves. As the next step, based on this technology, bench-scale equipment was built in the Hitachi Works and has now started operation to develop the technology for closed-loop recycling of automotive lithium-ion batteries.

The objective of building and operating this equipment is to produce recycled product samples using materials provided by automakers and battery manufacturers, and to establish a mass production process capable of processing at viable cost levels. A feature of the equipment is the high degree of freedom of the design, enabling various shapes to be created including liquids, salts, and metals. It is possible to recover cobalt, nickel, and lithium separately with battery-grade quality.

For recycling of automotive lithium-ion batteries to become firmly rooted, a society-wide system is essential, one that extends to recovery and dismantling. By establishing this recycling technology, the Company aims to play an active role in realizing such a system and to accelerate moves toward realizing it.

We are committed to continuing our efforts to meet the needs of the era by promoting initiatives for recycling valuable nonferrous metals, helping to realize a resource-recycling society.

* Continuously operating small-scale test equipment

Reference Materials (Photos)

◆Bench-scale equipment

◆Recovered rare metals

Salts

Liquids