Copper Alloys and Special Steel Products

Copper Alloy Strip

Features

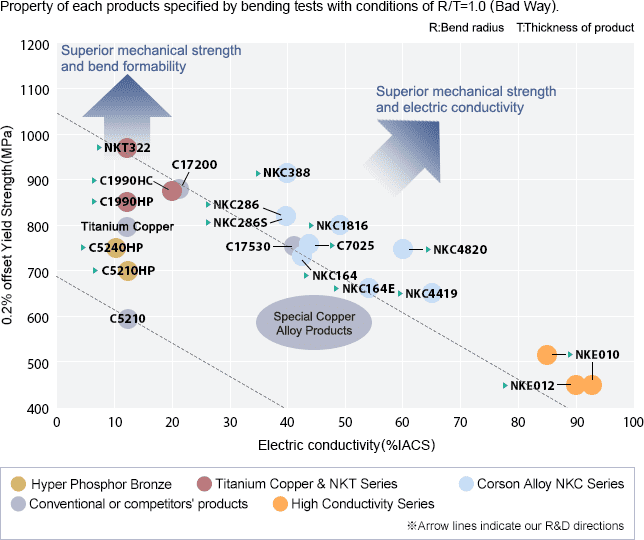

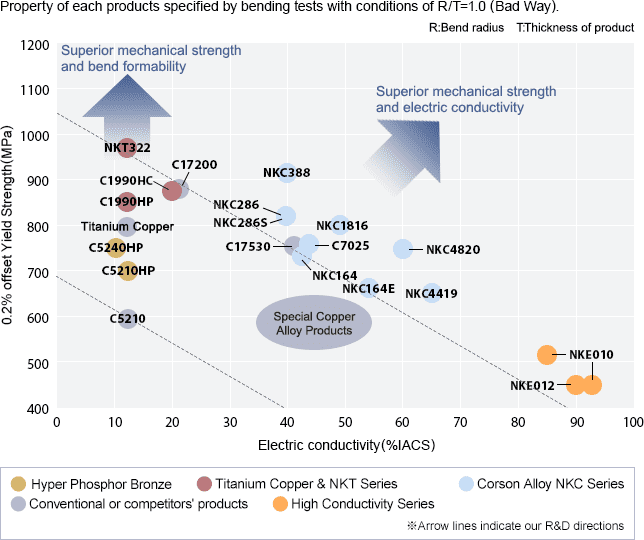

We provide products meeting customer requirements for strength, bend formability, and electrical conductivity.

Copper Alloy Lineup

Technology and Properties

Properties Map

Application

- Connectors

- Lead frames

- Connector for Automotive

- Switches

- Relays

| Explanation of technical terms |

|---|

Contact Information

From the Web

Inquiries accepted 24 hours a day