HA and HA-V2 ― Flexible rolled copper foil

Applications

- FPC for optical pickups

- FPC for hard disc drives

- FPC for LCD modules

- In-vehicle FPC

Features

- A treated rolled copper foil designed with large crystal grain and uniform crystal orientation.

- Outstanding flexibility minimizes cracking.

- Vibration resistance is greatly improved.

- High pliability due to low repulsive force.

Technical data and Properties

Crystal structure and outstanding properties of HA and HA-V2 foil

Recrystallized structure

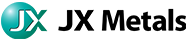

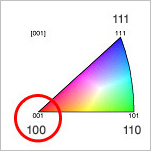

The large crystal grain and uniform crystal orientation of HA and HA-V2 foils give rolled copper foils outstanding 180 degrees folding endurance (i.e., static bendability), as well as IPC fatigue endurance (i.e., dynamic flexibility), low repulsive force, pliability, and excellent vibration resistance. The crystal grain is designed to grow very large after annealing, which minimizes cracking by decreasing the area of crystal grain boundaries where cracking can occur.

FIB-SIM views of copper foil cross-sections showing differences in crystal structures

Improvement of crystal orientation

HA and HA-V2 foils are designed so that after annealing, the crystalline structure becomes very strongly oriented to the (100) direction. This reduces mismatching at the crystal grain boundaries, preventing stress from building up in the foil from FPC folding, flexion, and vibration, and resulting in a foil that is resistant to metal fatigue and necking.

EBSP views of copper foil surfaces showing differences in crystal grain orientation

- Note that the greater the color uniformity, the more uniform is the crystal grain orientation.

Sliding (dynamic) bendability

HA and HA-V2 foils have greater flexibility than standard rolled copper foil.

Moreover, we provide an extremely thin copper foil product foil of 9 µm, in application involving smaller and thinner electronic devices.

Pliability

HA foil features outstanding pliability, with a lower Young's modulus than standard rolled copper foil and special electro-deposited copper foil.

Young's modulus of annealed foils

| Young's modulus/GPa | |

|---|---|

| HA foil | 70 |

| Ordinary rolled copper foil | 100 |

| Special electro-deposited copper foil | 115 |

Low repulsive force

HA foil with its low repulsive force is an ideal special rolled copper foil for applications where bending takes place in assembly.

Incorporating HA foil makes it possible to minimize flexible copper clad laminate (FCCL) springback.

Demonstrating low repulsive force by means of a loop stiffness tester

Evaluation in FCCL use

Folding resistance (static bendability)

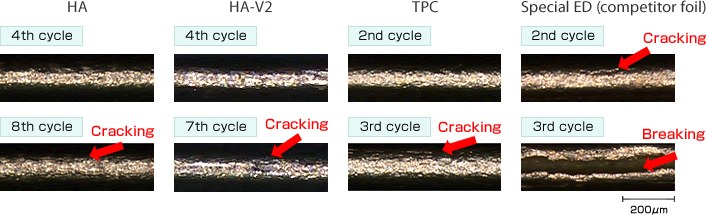

HA foil withstands repeated bending (folding) better than standard rolled copper foil. Using the test method shown below, FCCL was bent repeatedly at 180℃. With special electro-deposited copper foil, cracking appeared in the second cycle, whereas no cracking appeared in TPC foil up to the second cycle, in HA-V2 foil up to the fifth cycle, or in HA foil up to the sixth cycle of testing. HA foil, HA-V2 foil, and TPC foil are superior to special electro-deposited copper foil in terms of folding.

FCCL 180℃ bending test

Bending Properties Compared

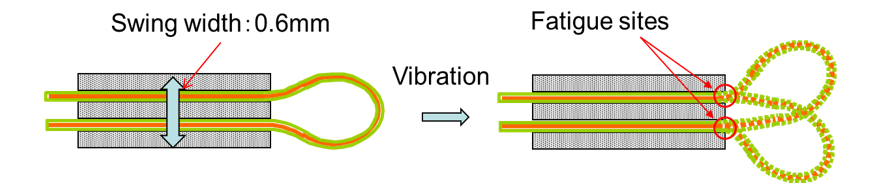

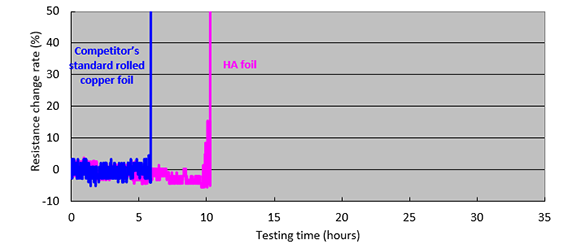

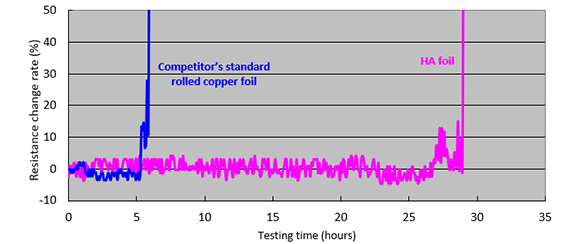

Vibration resistance

FCCL incorporating HA foil shows twice the vibration resistance of standard rolled copper foil at room temperature. At high temperature (115℃) it is approximately five times more resistant. In a temperature cycle test from -30℃ to 115℃, the lifetime is approximately three times that of standard rolled copper foil, as HA foil maintains its excellent vibration resistance even in harsh conditions.

Diagram of test procedure

Results of room temperature vibration testing at 5 to 170 Hz for HA foil and a competitor's standard rolled copper foil

Lifetime (time for resistance change rate to rise by 20%)

HA foil: 10 hours

Competitor's standard rolled copper foil: 6 hours

Results of 115℃ vibration testing at 5 to 170 Hz for HA foil and a competitor's standard rolled copper foil

Lifetime (time for resistance change rate to rise by 20%)

HA foil: 29 hours

Competitor's standard rolled copper foil: 6 hours

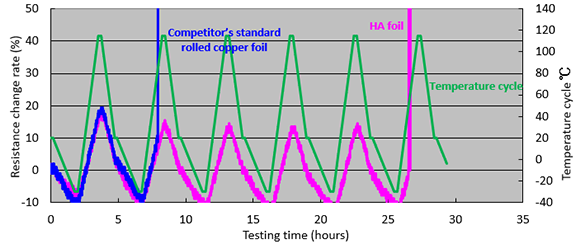

Results of -30 to 115℃ cycle vibration testing at 5 to 170 Hz for HA foil and a competitor's standard rolled copper foil

Lifetime (time for resistance change rate to rise by 20%)

HA foil: 26 hours

Competitor's standard rolled copper foil: 8 hours

The temperature cycle is shown by the green line.

The resistance change rate increases and decreases with the temperature cycle.

Inquiries accepted 24 hours a day.