Titanium Copper Alloy ― The best alternative to beryllium copper

Compare Features and Typical Applications

Titanium Copper Alloy

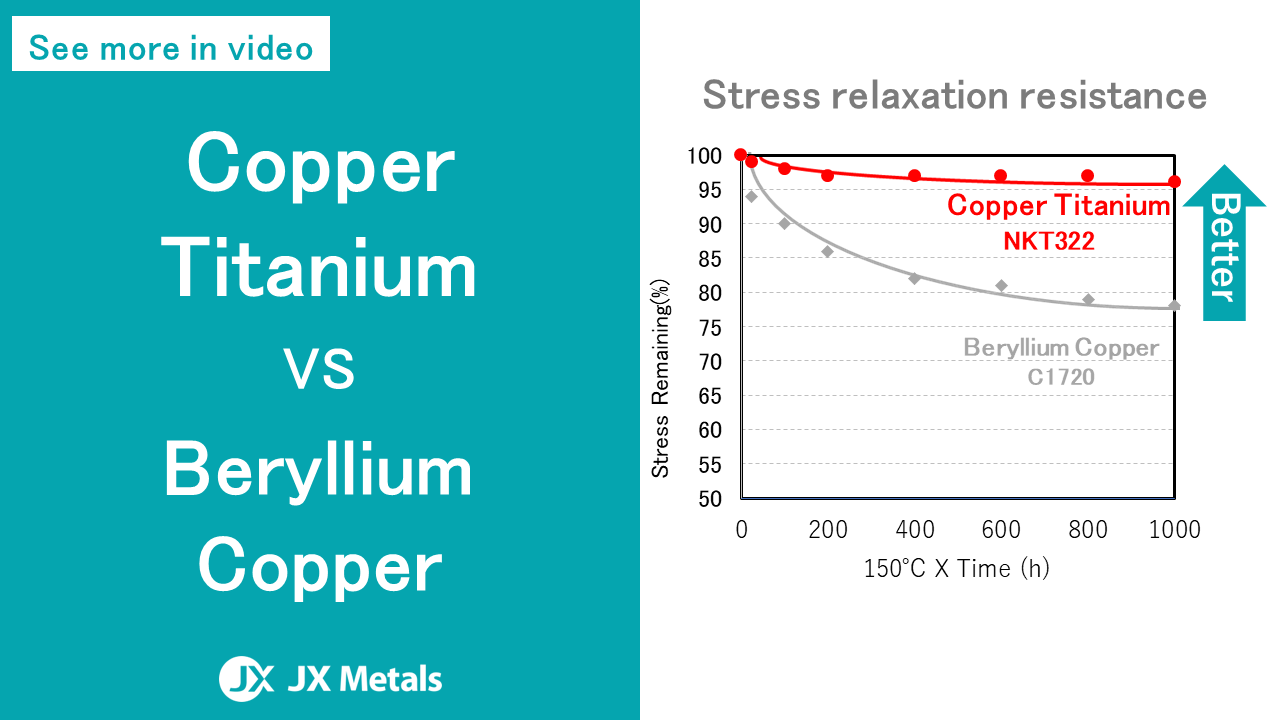

Titanium copper is a copper alloy having titanium as the main additive element. Advantages include high strength along with excellent stress relaxation resistance and bend formability. Its properties are superior to those of beryllium copper alloy, long a representative standard for high-functionality copper alloys.

Among the main uses are for connectors and camera modules in electronic devices such as smartphones and personal computers, taking advantage of the high strength and workability. Thanks to its outstanding stress relaxation resistance, use in automotive connectors has grown in recent years.

As applications grow and the properties customers demand become more advanced as a result, we will continue our technology development toward improving properties and expanding our alloy lineup, so that such needs can be met in timely fashion.

| Alloy name | Composition | Features | Applications |

|---|---|---|---|

| Cu-3Ti | High strength, superior stress relaxation resistance | Connectors, switches, jacks | |

| Cu-3Ti | Strength and bend formability superior to conventional titanium copper | Connectors, switches, jacks | |

| Cu-3Ti | A Hyper Titanium Copper foil product that has the highest level of strength of any copper alloy | Connectors, camera modules | |

| Cu-3Ti | Electrical conductivity superior to conventional titanium copper | Connectors, switches, battery terminals, jacks | |

| Cu-3.2Ti-0.2Fe | Strength (Yield strength) of 1 GPa or higher, along with excellent bend formability | Connectors, switches, jacks |

Compare Composition and Properties

Titanium Copper Alloy Composition and Properties

Chemical Composition (wt%)

| Copper Alloy Name | TiCu | |||

|---|---|---|---|---|

| C1990 | C1990HP | C1990HC | NKT322 | |

| Chemical Composition (wt%) | Cu : Bal. Ti : 3.0 |

Cu : Bal. Ti : 3.0 |

Cu : Bal. Ti : 3.0 |

Cu : Bal. Ti : 3.0 Fe : 0.2 |

Physical Properties

| Copper Alloy Name | TiCu | |||

|---|---|---|---|---|

| C1990 | C1990HP | C1990HC | NKT322 | |

| Specific Gravity (g/cm3) | 8.70 | 8.70 | 8.70 | 8.70 |

| Modulus of Elasticity (GPa) | 127 | 127 XSH:115 |

127 | 120 |

| Electrical Conductivity (%IACS@20℃) | 12 | 12 | 20 | 12 |

| Poisson's Ratio | 0.33 | 0.33 | 0.33 | 0.33 |

Mechanical Properties

| Copper Alloy Name | TiCu | ||||

|---|---|---|---|---|---|

| C1990 | C1990HP | C1990HC | NKT322 | ||

| Tensile Strength (MPa) | 1/4H | 735-930 | - | - | - |

| H | - | - | - | 900-1000 | |

| EH | 885-1080 | 885-1080 | (950) | 920-1020 | |

| SH | - | 910-1110 | - | 970-1100 | |

| ESH | - | 1000-1180 | - | 1010-1200 | |

| ESH (HB) | - | - | - | 1010-1200 | |

| XSH | - | 1050-1400 | - | - | |

| XSH (HB) | - | - | - | 1050-1250 | |

| GSH | - | 1300-1600 (thickness≦0.1mm) |

- | - | |

| 0.2% Yield Strength (MPa) | 1/4H | - | - | - | - |

| H | - | - | - | 800-900 | |

| EH | 800-900 | 820-920 | (900) | 850-950 | |

| SH | - | 850-950 | - | 900-1000 | |

| ESH | - | 940-1040 | - | 950-1050 | |

| ESH (HB) | - | - | 950-1050 | ||

| XSH | - | (1120) | - | - | |

| XSH (HB) | - | - | - | 1000-1100 | |

| GSH | - | (1390) | - | - | |

| Elongation (%) | 1/4H | 10min | - | - | - |

| H | - | - | - | 12min | |

| EH | 5min | 10min | (2.0) | 10min | |

| SH | - | 8min | - | 6min | |

| ESH | - | (3.0) | - | 3min | |

| ESH (HB) | - | - | - | - | |

| XSH | - | - | - | - | |

| XSH (HB) | - | - | - | - | |

| GSH | - | - | - | - | |

| Vickers Hardness (Hv) | 1/4H | 250min | - | - | - |

| H | - | - | - | (300) | |

| EH | 280min | (300) | (300) | (310) | |

| SH | - | (320) | - | (320) | |

| ESH | - | (340) | - | (340) | |

| ESH (HB) | - | - | - | (340) | |

| XSH | - | (340) | - | - | |

| XSH (HB) | - | - | - | (350) | |

| GSH | - | (400) | - | - | |

- Standard specs. (Typical values)

Bend Formability

| Copper Alloy Name | TiCu | |||||

|---|---|---|---|---|---|---|

| C1990 | C1990HP | C1990HC | NKT322 | |||

| Minimum Bend Radius / t Badway |

H | - | - | - | 0.0 | 0.5 |

| - | - | - | - | t ≦ 0.15 | 0.15 < t ≦ 0.25 | |

| EH | 4.0 | 1.0 | 0.0 | 0.5 | 1.0 | |

| - | - | - | (t ≦ 0.1mm) | t ≦ 0.15 | 0.15 < t ≦ 0.25 | |

| SH | - | 2.0 | - | 1.0 | 2.0 | |

| - | - | - | - | t ≦ 0.12 | 0.12 < t ≦ 0.22 | |

| ESH | - | ≧5.0 | - | 2.0 | 3.0 | |

| - | - | - | - | t ≦ 0.10 | 0.10 < t ≦ 0.20 | |

- Bad way 90°W-shape Bending Width=10mm

| Explanation of technical terms |

|---|

Inquiries accepted 24 hours a day